Dimethyl carbonate has been studied as an. A comprehensive review of the literature on the subject of biodiesel production was carried out.

Pdf Production Of Biodiesel Through Interesterification Of Triglycerides With Methyl Acetate

Ultrasonic Reactors Not widely practiced in current production Potential to dramatically reduce amount of catalyst used and reaction.

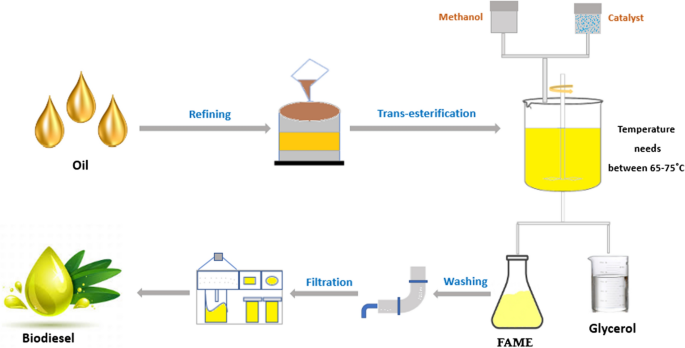

. The purpose of the transesterification process is to lower the viscosity of the oil. And glycerol is used in pellet formation. Table 9 compares the properties of produced canola biodiesel and diesel.

The conventional transesterification process used for biodiesel production leaves manufacturers with a byproduct glycerol that is of low value. This biodiesel is then tested for calorific value. 22 Flow Chart- Take Allow mixture to sit for about 24 hours 23 Calorific analysis-.

17042009 2 CSTR Plug flow High. Big potential for producing biodiesel because the developments in Indonesias Crude Palm Oil CPO production is increasing every year. Via transesterification process in the presence of catalyst.

Biodiesel has been prepared using Ultrasonic set-up. Types of Biodiesel Production Batch Process Most common small-scale and home-brewing process Slow reaction times 1-8 hrs. Traditionally biodiesel has been produced using either.

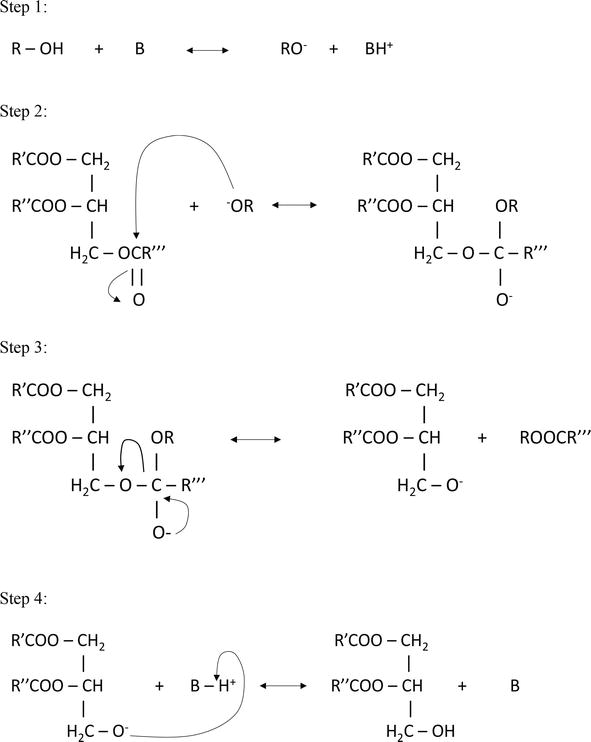

A typical mechanism of acid catalyzed transesterification of vegetable oils. Marine Fresh water Algae. In-line Shear Reactors Large-scale Fast reaction times 1-2 hrs.

Improvement of Biodiesel Production in Batch Transesterification Process. Biodiesel has emerged as a viable substitute for petroleum diesel. Based on the process effectiveness and production costs for equal other conditions.

The main objective of the work is to optimize the transesterification process for biodiesel production to yield biodiesel that has the best properties such as viscosity cetane number flash point fire point and calorific value. The main component of their canola oil biodiesel is methyl oleate which contains 6092 wt of this component. These catalysts give very high yields in alkyl esters but the.

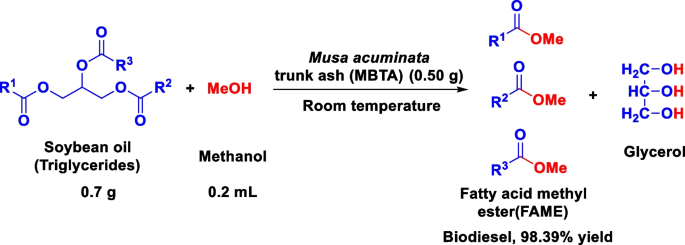

After ascertaining that the extracted Jatropha oil was suitable for biodiesel production it was employed in a transesterification reaction for the process and the results of the transesterification processes carried out are as outlined below. After twenty-five years of study the description of the kinetics of transesterification for biodiesel remains controversial. 3 Simulation results for transesterification of soybean oil and experimental results from work 2.

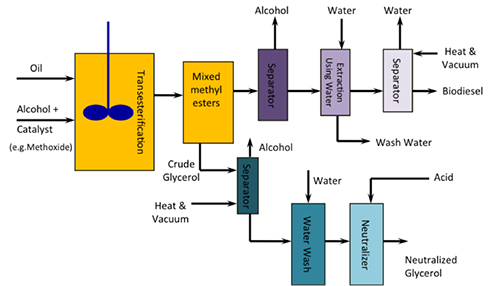

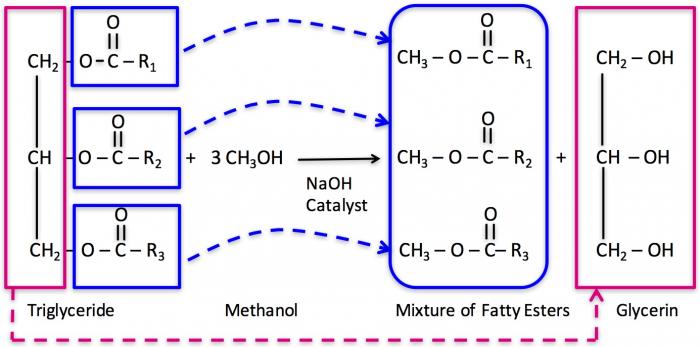

This research focuses on the transesterification process for biodiesel production because of its higher output efficiency reactivity with feedstock techno-economic feasibility in terms of FFA. By using the response surface methodology RSM the biodiesel production process was optimized to obtain the highest yield of biodiesel. Biodiesel is produced 8-by the transesterification reaction between lipids animal fats or plants and short chain of alcohol methanol or ethanol in a base or acid catalyst.

From which we get Biodiesel as product and glycerol as byproduct. Conventional diesel fuel was the base fuel for comparing the above. The fuel can be made easily from either virgin or waste vegetable oil.

Biodiesel Growth Conditions Biochemical Analysis pH. Based on the composition canola biodiesel contains a total of 1289 wt saturated FAME component 4261 wt monounsaturated FAME and 445 wt polyunsaturated FAME. Biodiesel yield recovery obtained from Base- transesterification process about 92.

And Cetane No of 4819. Preferably sulphonic and sulphuric acids are mostly used. By changing the methanol to methoxide ratio biodiesel is produced and yield is calculated.

Jatropha oil nonedible vegetable oil was used to produce biodiesel. The Biodiesel Production Process. Kinematic viscosity of biodiesel was found to be 551 mm.

The highest yield which is 95 is obtained with a 515 methanol to methoxide ratio. Biodiesel is mostly produced by a transesterification reaction from oil with an alcohol and the presence of a catalyst to generate mono-alkyl esters and glycerol which are then separated and purified 3. Reactor Design Culture Trans-esterification.

The transesterification process in biodiesel production is catalyzed by Bronsted acids like HCl BF 3 H 3PO 4 H 2SO 4 and sulphonic acids 4950. A common means of production is base-catalyzed transesterification. Methyl ethyl 2-propyl and butyl esters were prepared from vegetable oils through transesterification using potassium andor sodium alkoxides as catalysts.

Produced Biodiesel specifications were also analyzed and discussed in Base-transesterification process. Biomass Algae growth Results Heterotrophic growth Literature. Transesterification process design for biodiesel production.

At 40 C the flash point was 1742 C. 31Transesterification Process Using Literature Values Using the transesterification conditions obtained from the work of. In this study vegetable oil methanol and a homogenous alkaline catalyst 15 are studied.

In order to design an economically and environmentally sustainable biodiesel production process a proper understanding of the factors affecting the process and their relative importance is necessary.

Pdf Base Transesterification Process For Biodiesel Fuel Production From Spent Frying Oils

Widely Used Catalysts In Biodiesel Production A Review Rsc Advances Rsc Publishing Doi 10 1039 D0ra07931f

Enzyme Transesterification Process The Resulting Products Of This Download Scientific Diagram

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram

Transesterification Srs Biodieselsrs Biodiesel

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

Evc1 Transesterification To Biodiesel

A Sustainable Protocol For Production Of Biodiesel By Transesterification Of Soybean Oil Using Banana Trunk Ash As A Heterogeneous Catalyst Springerlink

Transesterification An Overview Sciencedirect Topics

Role Of Microbial Lipases In Transesterification Process For Biodiesel Production Springerlink

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

Transesterification Srs Biodieselsrs Biodiesel

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

In Situ Transesterification Process For Biodiesel Production Using Spent Coffee Grounds From The Instant Coffee Industry Sciencedirect

Transesterification An Overview Sciencedirect Topics

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

Transesterification An Overview Sciencedirect Topics

Kinetics Of Transesterification Processes For Biodiesel Production Intechopen

Transesterification An Overview Sciencedirect Topics